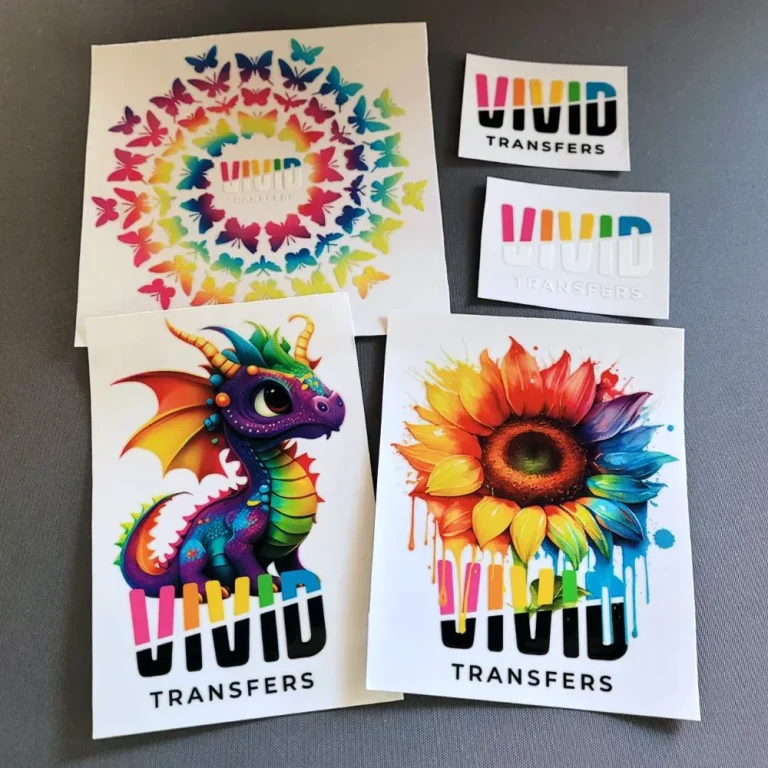

UV DTF transfers are revolutionizing the printing landscape, offering a versatile solution for creating stunning visuals on a variety of surfaces. This innovative technology combines the benefits of UV printing and DTF (Direct to Film) methods, allowing for vibrant, long-lasting designs that stand out. Whether you’re customizing apparel, designing promotional merchandise, or crafting unique art pieces, UV DTF transfers provide the perfect canvas for your creativity. In this guide, we will share essential creative design tips and techniques that highlight the potential of transfer films and layering methods. Get ready to explore how UV DTF can elevate your printing projects to new heights!

The realm of direct-to-film printing has opened up new avenues for artists and designers, particularly through the integration of UV technology. Often referred to as UV transfer printing, this process merges the durability of ultraviolet inks with the flexibility of DTF techniques, enabling exceptional image quality and detail. This method is ideal for various applications, from fashion to promotional items, and utilizes innovative layering techniques for enhanced visual effects. In this article, we will delve into effective strategies and creative design tips that can maximize your potential using these advanced printing methods. Join us as we navigate the exciting possibilities that UV DTF presents.

The Benefits of UV DTF Transfers

UV DTF transfers come with a host of benefits that make them a popular choice for both professional and hobbyist printers. Firstly, the vibrant colors achievable through UV DTF technology allow for eye-catching designs that stand out. Unlike traditional printing methods, UV DTF utilizes advanced inks that resist fading and degradation, ensuring that your prints maintain their brilliance over time. This durability is particularly beneficial for items that may be subjected to wear and tear, such as clothing or promotional merchandise.

Moreover, UV DTF transfers offer incredible versatility, allowing users to print on a wide range of substrates, from textiles to hard materials like wood and metal. This flexibility opens up a plethora of creative possibilities for custom projects. Whether you’re designing t-shirts, decals, or unique promotional items, the adaptability of UV DTF ensures that you can easily experiment with different materials to achieve the desired look and feel.

Key Considerations for Material Selection

When it comes to UV DTF transfers, selecting the right materials is crucial to achieving the best results. High-quality **transfer films** that are specifically designed for UV printing are essential for optimal adhesion and longevity of the prints. The film you choose should have a surface that can hold ink effectively while also maintaining its integrity through the transfer process. Opting for inferior materials not only compromises the print quality but can also lead to issues like cracking or peeling over time.

In addition to choosing the right transfer films, it’s important to consider the substrates on which the designs will be applied. Compatibility between the film and the substrate can greatly affect print durability and adhesion. For instance, while a glossy finish might look stunning on certain materials, it might not hold up as well on others. Therefore, testing different combinations before committing to a large print run can help mitigate potential challenges and enhance overall creative output.

Exploring Textures and Finishes

One of the exciting aspects of UV DTF printing is the ability to explore various textures and finishes, which can dramatically alter the perception of your designs. Using **matte, gloss, or textured films** in your projects provides an opportunity to enhance visual interest. A matte finish may lend a subtle elegance to the design, while high-gloss finishes can make colors pop and appear more vivid. The choice of finish not only impacts aesthetics but can also affect the tactile experience of the final product.

Incorporating different finishes allows for creative experimentation that can set your work apart. For example, combining a matte background with glossy elements creates a striking contrast that can draw the viewer’s eye. Designers should consider how these finishes interact with light and texture to tell a story or complete a brand’s visual identity. By understanding and utilizing the range of textures available, you can elevate your print designs to new artistic heights.

Effective Layering Techniques

Layering techniques in UV DTF transfers can profoundly impact the depth and complexity of your designs. By thoughtfully combining colors and effects, you can create striking visuals that capture attention. Utilizing various opacities and blending modes in design software can lead to multi-dimensional output that adds intrigue and sophistication. For instance, layering transparent colors allows the underlying layers to blend, forming unique shades and textures that wouldn’t be achievable in a single print.

Aside from aesthetic appeal, effective layering can enhance the vibrancy of your designs. Each layer acts not only as a color component but as a means of building depth through texture and light play. This technique is invaluable for intricate designs where details are paramount. Learning and experimenting with layering techniques can ultimately empower your creative vision, allowing you to produce striking artworks that stand out in the crowded printing market.

Precision in Digital Design

Precision is key to successful UV DTF transfers, starting from the digital design stage. Ensuring that your files are perfectly formatted—paying attention to resolution, dimensions, and bleed—is essential to avoid mishaps during the printing process. A well-prepared file can make the difference between sharp, professional-looking prints and amateurish results that fail to meet expectations. Therefore, investing time upfront in your design accurately pays off during production.

Additionally, understanding the specific technical requirements of UV DTF printing will greatly improve your output quality. Familiarizing yourself with the printer settings and specs can help you align your digital creation with the hardware capabilities. Taking the extra effort to double-check all aspects of your design file not only boosts the likelihood of achieving your desired results, but it also enhances your overall credibility as a designer in the competitive world of printing.

Staying Current with UV DTF Innovations

In the rapidly evolving field of UV printing, staying informed about the latest innovations is crucial for every designer and printer. With new technologies and materials emerging regularly, being proactive in seeking out current trends can spark creativity and inspire new project ideas. Engaging with industry publications, attending trade shows, and participating in online forums can offer invaluable insights that keep you ahead of the curve.

Moreover, understanding contemporary practices not only helps refine your techniques but can also inspire collaborative approaches to design. As you connect with other creatives in the field, sharing ideas and experiences can lead to innovative projects that may incorporate newer technologies, such as advanced layering techniques or eco-friendly materials. Embracing lifelong learning will not only enhance your skill set but also foster an environment of creativity that can benefit your work and business.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers, or UV Direct to Film transfers, are an innovative printing technique that applies eco-friendly inks directly onto a specially coated film. After printing, images can be transferred onto various substrates, such as textiles and promotional items, resulting in vibrant and durable designs that withstand wear and tear.

How do color profiles affect UV DTF printing?

Color profiles play a critical role in UV DTF printing as they help ensure color accuracy. Utilizing correctly calibrated monitors and ICC profiles specific to your inks and printer allows you to achieve stunning, true-to-life colors in your final prints.

What materials are best for UV DTF transfers?

Selecting high-quality transfer films designed specifically for UV printing is essential for successful UV DTF transfers. The right materials promote optimal adhesion and durability, while inferior options can compromise print quality and lead to premature wear.

What are some creative design tips for UV DTF printing?

To maximize creativity in UV DTF printing, experiment with textures, finishes, and layering techniques. Using matte or gloss films can impact how your design is perceived, while effective layering can create depth and vibrancy, transforming your visuals.

What is the importance of precision in UV DTF design preparation?

Precision in preparing digital files for UV DTF printing is crucial. Properly formatting files with the correct resolution, dimensions, and bleed settings helps to avoid issues during the printing process, ensuring the final output captures your creative vision accurately.

How can I stay updated on the latest UV DTF printing innovations?

Staying informed about the latest trends and innovations in UV DTF printing is vital for sparking creativity. Engage with industry forums, read relevant publications, and connect with fellow creatives to share insights and inspire new design directions.

| Tip | Description |

|---|---|

| Understanding Color Profiles | Calibrate monitors and use ICC profiles for accurate color output. |

| Choosing the Right Materials | Select high-quality films and substrates to ensure durability and print quality. |

| Experiment with Textures and Finishes | Use matte, gloss, or textured finishes to enhance design appeal. |

| Layering Techniques | Layer colors for depth using various opacities and blending modes. |

| Precision in Design | Ensure digital files are correctly formatted to avoid printing issues. |

| Training and Tools | Invest in training and use modern software to maximize capabilities. |

| Stay Updated on Innovations | Continuously learn about new trends and technologies in UV DTF. |

Summary

UV DTF transfers represent a remarkable opportunity for creators to explore innovative printing techniques. To truly maximize your creativity in UV DTF transfers, it’s essential to master various components such as color profiles, material selection, and layering techniques. By experimenting with finishes and ensuring precision in your design files, you can produce exceptional results that stand out. Moreover, continuous learning about industry innovations and utilizing effective training can further enhance your capabilities. Embrace these practices to fully unlock the potential of your UV DTF projects, allowing your creativity to shine through.