UV DTF Transfers are revolutionizing the printing industry by blending cutting-edge UV printing technology with the versatility of Direct-to-Film (DTF) printing. This innovative method allows for the transfer of vibrant, intricate designs onto a wide range of substrates, enhancing creative opportunities for businesses and designers alike. As a result, UV DTF printing has become a preferred solution for those seeking sustainable printing approaches that minimize environmental impact. With its ability to produce high-quality images without the need for white ink underlays, this technology is particularly beneficial for apparel printing innovations. Dive into the world of UV DTF Transfers as we explore how this creative printing solution is reshaping industries and sparking inspiration among artists.

Introducing UV Direct-to-Film transfers, a groundbreaking technique that fuses the advancements of ultraviolet printing with the adaptability of direct film applications. This method is gaining traction in the realm of innovative printing solutions, allowing for exceptional detail and color vibrancy on various surfaces, including textiles and plastics. As more businesses pivot toward sustainable printing practices, the efficiency of this technology stands out, catering particularly to the needs of modern apparel printing trends. Moreover, the ability to transfer eye-catching designs without extensive pre-treatment makes it a game-changer for custom work. In this discussion, we will delve into the potential and versatility of these state-of-the-art printing methods, highlighting their impact on creative expression.

Understanding the Basics of UV DTF Printing

UV DTF printing stands at the forefront of modern printing technology, marrying the robust traits of UV printing with the adaptability of DTF methods. This innovative process utilizes UV-curable inks that are printed onto a film, which can easily be transferred onto various substrates including fabrics and plastics. By harnessing this technology, businesses can achieve vivid prints that maintain integrity over long periods, making it a preferred choice for many in the apparel production and promotional merchandise industries.

Unlike traditional printing techniques that may require extensive preparatory steps, UV DTF printing offers a streamlined approach. It eliminates the need for a white underlay, which is often essential when printing on darker materials, thereby paving the way for a broader spectrum of creative possibilities. This advancement not only enhances the visual appeal of the prints but also significantly reduces production time, empowering businesses to meet tight deadlines while maintaining high standards of quality.

The Benefits of UV DTF Transfers

One of the most remarkable advantages of UV DTF transfers is their ability to produce high-quality, durable prints that withstand the rigors of everyday use. The vibrant colors achievable through this method can make any item stand out, which is particularly beneficial in the competitive world of custom apparel and promotional products. Businesses that utilize UV DTF technology can create designs that are not only striking but also long-lasting, appealing to consumers looking for quality.

Sustainability is another key benefit associated with UV DTF transfers. The technology employs inks that emit low levels of volatile organic compounds (VOCs), aligning with eco-friendly printing practices. This attribute is increasingly important as consumers gravitate towards products that reflect environmental consciousness. Moreover, given the reduced ink waste due to the efficient curing process, UV DTF printing presents an ideal solution for companies striving to minimize their carbon footprint.

Creative Applications of UV DTF Technology

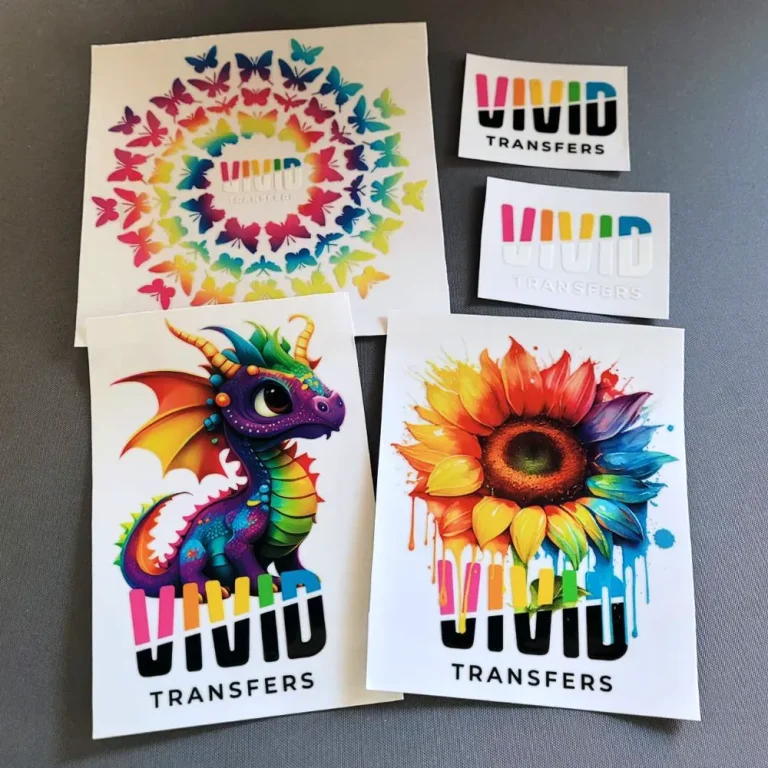

The versatility of UV DTF printing extends far beyond just apparel; it caters to a vast array of applications including customized promotional items and unique décor. For instance, businesses can create promotional products such as customized bags, mugs, and promotional materials that captivate customers with their distinct designs. This flexibility allows brands to maintain their uniqueness in a saturated market, enhancing their visibility and customer engagement.

Additionally, artists and designers are utilizing UV DTF technology to push the boundaries of creativity in the art realm. This method facilitates the creation of striking wall art and home decor items that can showcase intricate patterns and vibrant images. By allowing artists to explore new dimensions in their work, UV DTF printing is transforming the landscape of art and design, thus fueling innovation across various creative sectors.

Combating Challenges in UV DTF Printing

Despite the numerous benefits of UV DTF printing, challenges persist, particularly regarding the upfront investment in high-quality printers. Startups and smaller businesses may find the initial costs daunting. However, with the rapid advancements in printing technology, manufacturers are now offering more compact and user-friendly machines that come at a lower price point, making them accessible to a wider audience.

Moreover, the industry is gradually addressing the skill gaps in operating these advanced printers. Training and education on best practices for UV DTF printing can help new users navigate the complexities involved, ultimately facilitating smoother integration into their existing production processes. As the market evolves and more resources become available, businesses will be better equipped to harness the full potential of UV DTF technology.

The Future of Printing with UV DTF

UV DTF printing is poised for a dynamic future as it evolves alongside technological advancements. The incorporation of smart printing techniques and AI-driven design software is likely to enhance the capabilities of UV DTF printing even further. This evolution will not only streamline production processes but also encourage artists and designers to explore even bolder expressions in their work.

With increasing consumer demand for customized products and sustainable practices, UV DTF printing stands to benefit significantly. As businesses continue to seek ways to differentiate their product lines, leveraging the latest in UV DTF technology will enable them to meet these expectations creatively and efficiently, solidifying their standing in the fast-paced print and apparel markets.

Exploring Market Trends in UV DTF Printing

The UV DTF printing market is witnessing unprecedented growth, driven by rising demands for high-quality printing solutions in various sectors. As businesses increasingly recognize the potential of UV DTF technology, the market is expanding rapidly, particularly among small to medium-sized enterprises. This trend signals a willingness to adopt innovative printing methods that align with modern consumer demands.

In addition, the industry has seen a surge in research and development, leading to continuous improvements in equipment and inks used in UV DTF printing. Manufacturers are striving to innovate further, with expectations that upcoming models will feature enhanced capabilities for speed, quality, and sustainability. These advancements are essential as they provide businesses with the tools necessary to remain competitive and meet evolving market needs.

Frequently Asked Questions

What are UV DTF Transfers and how do they work?

UV DTF Transfers, or UV Direct-to-Film Transfers, use UV printing technology to apply vibrant inks onto a flexible film, which is then heat-transferred onto various substrates like textiles and plastics. This process allows for highly detailed and colorful designs without needing a white ink underlayer, making it ideal for apparel printing.

What advantages does UV DTF printing offer over traditional DTF methods?

UV DTF printing combines the advantages of UV printing technology with the flexibility of traditional DTF printing. It produces vibrant, high-quality prints, works well on a variety of materials, and has an eco-friendly profile due to lower VOC emissions and reduced ink waste during the curing process.

Can UV DTF Transfers be used on dark fabrics?

Yes, UV DTF Transfers can be applied to dark fabrics without the need for underlay white inks, which simplifies the process of producing colorful designs on darker materials. This capability enhances creativity in apparel printing, allowing for striking visual impacts.

Are UV DTF Transfers environmentally friendly?

Yes, UV DTF Transfers utilize UV inks that are designed to minimize environmental impact, emitting low VOCs during the printing process. The quick curing of the inks also reduces waste, making UV DTF printing a sustainable solution for creative printing applications.

What materials can be printed with UV DTF technology?

UV DTF technology is versatile and can print on a wide range of materials, including textiles, plastics, metals, and more. This adaptability enables businesses to explore multiple applications, from custom apparel to promotional products and home decor.

What challenges do businesses face when adopting UV DTF printing?

While UV DTF printing offers numerous benefits, challenges include the initial investment in high-quality printers and the learning curve associated with using advanced equipment. However, ongoing innovations are making these systems more accessible, helping businesses to overcome these initial hurdles.

| Key Points | Details |

|---|---|

| What is UV DTF Printing? | A printing method using UV inks on flexible films, suited for various substrates like textiles, plastics, and metals. |

| Advantages | 1. Produces vibrant, high-quality prints. 2. Versatile for various materials. 3. Eco-friendly with low VOC emissions. 4. Rapid market growth and accessibility. |

| Applications | 1. Custom apparel (e.g., t-shirts, bags). 2. Promotional products (e.g., mugs, coasters). 3. Art and decor items. |

| Challenges | 1. Initial investment costs for high-quality printers. 2. Learning curve for operation. 3. Ongoing innovations to address challenges. |

| Future Outlook | UV DTF printing is set to redefine creativity in print, allowing intricate designs and innovation in artistic expression. |

Summary

UV DTF Transfers are revolutionizing the print and garment decoration industries by merging the benefits of UV printing with traditional DTF techniques. This innovative method allows for exceptionally vibrant and detailed prints on a variety of substrates, from fabric to plastic and metal. The versatility and eco-friendliness of UV DTF Transfers cater to the growing need for sustainable practices in printing, making it a favorite among businesses and designers alike. As this technology continues to evolve, it will undoubtedly unlock new creative possibilities, enabling artists and brands to push the boundaries of design and customization.