DTF gangsheet printing is revolutionizing the world of custom apparel printing, offering a unique blend of efficiency and creativity. This innovative technique allows print enthusiasts to transfer multiple designs onto a single sheet of film, optimizing material usage while maintaining high-quality results. As direct-to-film (DTF) printing continues to gain traction, understanding gangsheet tips becomes essential for success in this competitive landscape. In today’s blog post, we will delve into the core elements that can enhance your DTF gangsheet printing skills, whether you are just starting or are already a seasoned professional. Get ready to elevate your printing game!

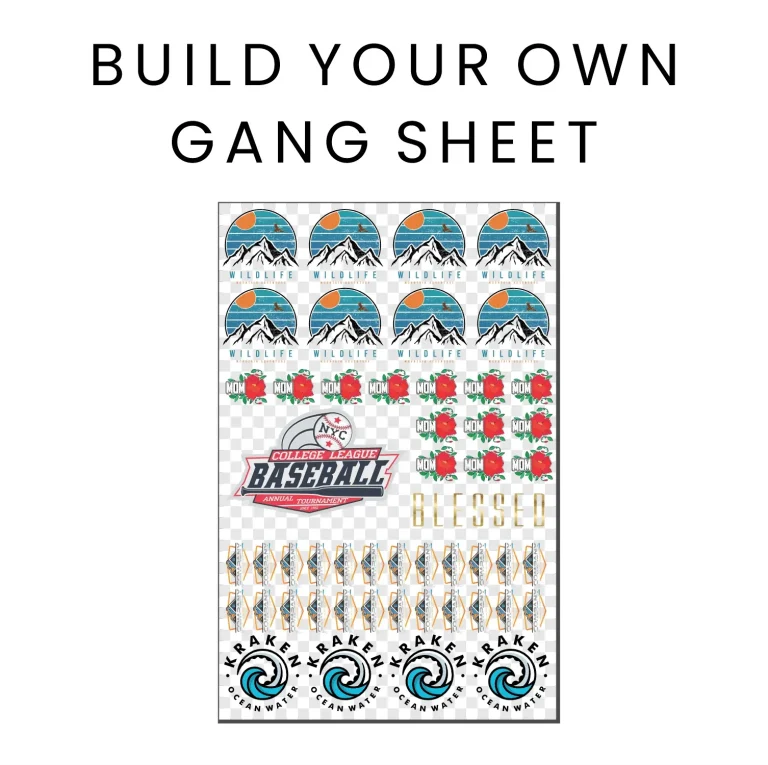

Exploring the realm of gangsheet printing, one finds a powerful method for maximizing output in direct-to-film applications. This approach allows designers to congregate various images onto one film sheet, thereby streamlining the overall printing process and reducing waste. With the rise of custom apparel fabrications, knowing the intricacies of laying out your graphics effectively can prove indispensable. Alternative expressions such as “film sheet printing” highlight the efficiency at which printers can operate, resulting in cost-effective solutions for bulk orders. Discovering tips and techniques for mastering this innovative printing method opens new doors for productivity and creativity.

Understanding DTF Gangsheet Printing: A Game Changer

DTF gangsheet printing is a revolutionary technique that allows for the printing of multiple images on a single film sheet. This approach streamlines the production process, minimizes waste, and reduces costs, making it an attractive option for custom apparel printing. By utilizing this method, printers can achieve high-quality results while maintaining efficiency in their operations, which is essential for both beginners and seasoned professionals alike.

One of the key advantages of gangsheet printing is that it maximizes the use of materials. Instead of printing images individually, which can be time-consuming and wasteful, gangsheet printing allows for a compact layout of designs on one sheet. This not only enhances productivity but also ensures that users can cater to bulk orders without compromising on quality, positioning them competitively in the fast-paced custom apparel market.

Essential Equipment for Effective DTF Printing

Selecting the right equipment is crucial for successful DTF printing, especially when it comes to the printer. High-quality DTF printers from popular brands such as Epson and Brother are widely recognized for their durability and exceptional output quality. Moreover, features such as high-resolution output and compatibility with various transfer films can significantly influence the quality of prints, making careful selection essential for both beginners and professionals.

In addition to a quality printer, investing in essential accessories can elevate your DTF printing experience. Quality transfer films and reliable inks tailored for direct-to-film application can enhance the durability of the prints and color vibrance. A dependable heat press is also a vital component, ensuring that prints are transferred effectively onto garments under controlled conditions. Together, these tools create a powerful setup that maximizes the potential of DTF gangsheet printing.

Mastering Material Selection for DTF Printing

The choice of materials is fundamental in DTF printing, as it greatly impacts the final print quality. High-quality DTF films made from Polyethylene Terephthalate (PET) are recommended due to their strength and ability to hold vibrant colors. Selecting the right materials is not just about print quality; it also affects print adhesion and longevity. Therefore, investing in premium inks and films specifically designed for DTF processes is essential.

Avoiding low-quality materials is equally important, as these can lead to poor adhesion and diminished print durability. When selecting materials, consider factors such as the fabric type and intended use of the printed apparel. Proper evaluation of materials ensures that the final product meets customer expectations and stands up to wear and tear, reinforcing the need for quality in every aspect of the DTF gangsheet printing process.

Design Preparation Tips for High-Quality Prints

Proper design preparation is critical in achieving optimal results in DTF gangsheet printing. Utilizing design software like Adobe Illustrator or CorelDRAW helps streamline this process. Ensuring that the files are correctly formatted for print is vital; for instance, maintaining a resolution of at least 300 DPI guarantees that images appear sharp and professional. Color consistency is another important aspect, where using CMYK color profiles prevents discrepancies during printing.

Design layout also plays a significant role in optimizing gangsheet printing. By carefully arranging graphics on the film sheet, users can maximize the use of space and minimize waste. Professionals should utilize design templates or guides that can assist in visualizing how designs will spatially occupy the film, thereby optimizing the output and ensuring that prints align perfectly during the transfer to fabrics.

Optimizing the Printing Process with Effective Techniques

Optimizing print settings can greatly influence the overall quality of DTF prints. Each DTF printer will have specific settings that must be adjusted based on the type of film being used, including temperature, ink saturation, and print speed. It’s beneficial to experiment with different settings to find the perfect combination for the specific materials being used. Regular calibration of the printer will also ensure that high standards of print quality are consistently met.

The printing process should not end with optimizations; attention to the heat application methodology is equally important. Using a heat press rather than a household iron ensures that the prints adhere properly to the garments. A properly set heat press, typically around 320°F for 10-15 seconds, applies the correct pressure and time for a successful transfer. This method guarantees durable and long-lasting results, elevating the quality of DTF gangsheet printing and offering significant value in the custom apparel market.

Troubleshooting Tips for Common DTF Printing Issues

Encountering challenges during the DTF printing process is not uncommon. Issues such as ink clogging and poor print adhesion can hamper production efficiency. To tackle these problems, implementing regular maintenance routines is crucial. Cleaning print heads and ensuring that fabrics are pre-treated adequately before applying DTF prints can enhance adhesion and reduce the likelihood of errors, ultimately improving output quality.

Joining online communities can further aid in troubleshooting challenges faced during DTF printing. Engaging in forums and social media groups dedicated to DTF printing allows users to share experiences, gather insights from peers, and learn from professionals in the industry. This collaborative approach to problem-solving not only fosters a supportive environment for newcomers but also enhances one’s skills through shared knowledge and best practices.

Frequently Asked Questions

What is DTF gangsheet printing and how does it work?

DTF gangsheet printing, or Direct-to-Film gangsheet printing, is a technique that allows multiple images to be printed on a single film sheet. This method is highly efficient for custom apparel printing as it reduces waste and lowers production costs. By preparing a gangsheet layout, users maximize material utilization, making it easier to transfer multiple designs onto garments.

What equipment do I need for successful DTF gangsheet printing?

To achieve high-quality DTF gangsheet printing, you need a reliable DTF printer, such as those from Epson or Brother, that can handle high-resolution prints. Additionally, quality DTF transfer films, inks, and a heat press are essential accessories. A good heat press ensures even pressure and temperature application during the transfer process, leading to better adhesion and durability of prints.

What are some tips for preparing designs for DTF gangsheet printing?

When preparing designs for DTF gangsheet printing, use design software like Adobe Illustrator or CorelDRAW. Ensure your graphics are formatted for print at a minimum of 300 DPI and use CMYK color profiles to ensure accurate color reproduction. Consider the layout of multiple designs on the gangsheet to optimize material usage and printing efficiency.

How do I optimize my print settings for DTF gangsheet printing?

Optimizing print settings for DTF gangsheet printing involves adjusting temperature, ink saturation, and print speed based on the specific film used. Regularly calibrate your printer for optimal performance and test different settings to find the best balance for your printing needs. This attention to detail will improve the quality of your final prints.

What common issues might I face with DTF gangsheet printing and how can I address them?

Common issues with DTF gangsheet printing include ink clogging and poor print adhesion. Regular maintenance of your printer, such as cleaning print heads, can help prevent ink clogging. Pre-treating fabrics before applying DTF prints can significantly enhance adhesion. Staying engaged with online communities can also provide solutions to challenges you encounter.

Are there any recent trends in DTF gangsheet printing that I should know about?

Yes, recent trends in DTF gangsheet printing include a growing focus on sustainable practices, with many manufacturers developing eco-friendly inks and films. Additionally, increased accessibility to DTF technology is enabling more small businesses and hobbyists to enter the market. Educational resources like workshops and online courses are also expanding, making it easier to master DTF techniques.

| Key Point | Description |

|---|---|

| What is Gangsheet Printing? | A technique that combines multiple graphics on one film sheet, optimizing production and reducing costs. |

| Choosing the Right Equipment | Invest in quality DTF printers like Epson or Brother, along with essential accessories such as transfer films and heat presses. |

| Material Selection | Use high-quality DTF films (like PET) and inks to ensure vibrant colors and strong adhesion. |

| Preparing Your Designs | Utilize software like Adobe Illustrator to create designs with at least 300 DPI and CMYK color profile. |

| Navigating the Printing Process | Optimize printer settings for each type of film and maintain regular calibration for best results. |

| Using a Heat Press | Utilize a heat press for applying designs, ensuring even pressure and temperature for durability. |

| Troubleshooting Issues | Regular maintenance can resolve ink clogging and adhesion problems; consider pre-treating fabrics. |

| Recent Trends | Watch for sustainable practices and increased accessibility for small businesses in DTF printing. |

Summary

DTF gangsheet printing provides an innovative approach to custom apparel production, allowing creators to optimize material use and streamline processes. By understanding the fundamentals, from equipment selection to design preparation, enthusiasts can leverage this method for vibrant, high-quality outputs. With ongoing advancements and community support, DTF gangsheet printing not only meets the needs of beginners but also enhances the skills of seasoned professionals seeking to push the boundaries in the printing landscape.