In the ever-evolving landscape of digital printing, **UV DTF transfers** (Direct to Film) have revolutionized the way products are decorated and personalized. This innovative technology leverages ultraviolet light to cure inks, resulting in prints that boast **high color vibrancy** and exceptional durability. Not only do these transfers create eye-catching designs, but they also offer unparalleled versatility across various substrates, including fabrics, plastics, and metals. Furthermore, UV DTF transfers prioritize eco-friendly practices by utilizing low-VOC inks, making them an attractive option for environmentally conscious consumers. With cost-effective production capabilities, this printing method presents businesses with a sustainable solution that doesn’t compromise on quality or visual appeal.

When it comes to modern printing solutions, **UV DTF technology** stands out for its transformative impact on how businesses create and enhance their products. Often referred to as direct-to-film printing, this technique employs ultraviolet light to set inks, delivering results that are both vibrant and robust. The adaptability of UV DTF allows for a wide array of substrates, enabling creators to print on anything from apparel to promotional materials with ease. Additionally, with a focus on sustainability, manufacturers are turning to this method to reduce their environmental footprint while maintaining high-quality outputs. In terms of efficiency and cost-effectiveness, UV DTF printing is paving the way for improved production processes in various industries.

Understanding UV DTF Transfers and Their Impact on the Printing Industry

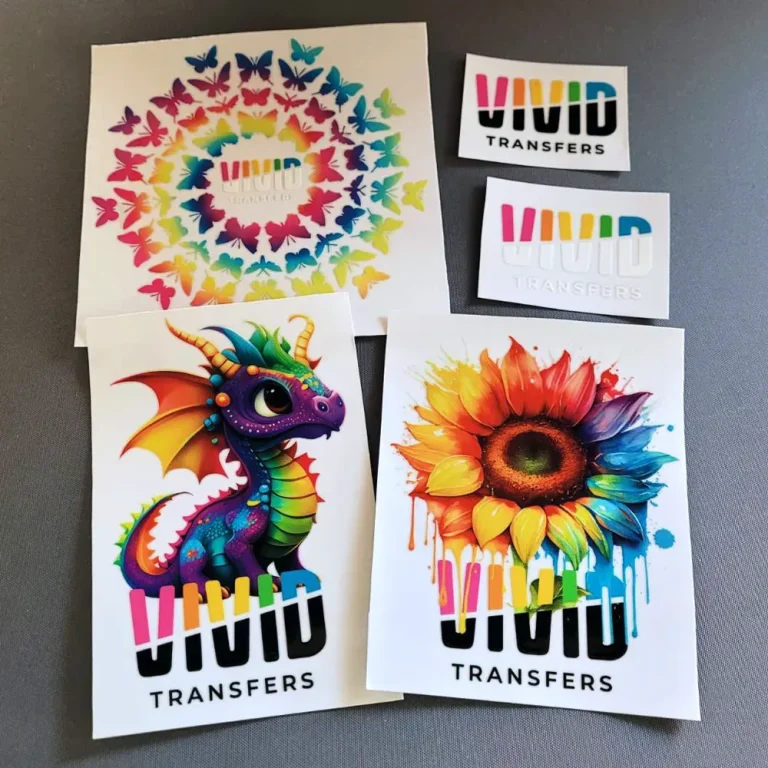

UV DTF transfers, or ultra-violet direct-to-film transfers, are revolutionizing the digital printing landscape by introducing a process that enhances color vibrancy and durability. Unlike traditional DTF methods, UV DTF utilizes cutting-edge UV light technology to cure inks as they are applied, allowing for an unparalleled range of colors that can bring designs to life. This process has opened up new avenues for businesses to create eye-catching products that demand attention in a crowded market.

Incorporating UV DTF transfers not only elevates the aesthetic quality of the prints but also promises longevity. The UV curing process ensures that the ink properly adheres to various substrates, resulting in prints that maintain their vibrancy and detail even under challenging conditions. As a result, businesses can leverage UV DTF technology to differentiate themselves from competitors while delivering high-quality, durable products.

The Role of High Color Vibrancy in Marketing

High color vibrancy is a crucial factor in the effectiveness of marketing materials and product designs. UV DTF transfers excel in this respect by providing a richer, more diverse color palette that significantly enhances visual appeal. For brands seeking to make a memorable impression, employing UV DTF printing can dramatically increase the attractiveness of promotional items, apparel, and point-of-sale displays.

Additionally, vibrant colors have been shown to positively affect consumer behavior, drawing attention and increasing engagement rates. By utilizing UV DTF transfers, businesses not only create stunning visuals but also strategically position themselves to resonate with target audiences. This approach ensures that the longevity of high-quality designs translates into lasting brand recognition and loyalty.

Examining the Durability of UV DTF Prints

One of the distinguishing features of UV DTF transfers is the exceptional durability of the final product. Thanks to the UV curing process, prints are not only resistant to fading but can withstand scratching and abrasion as well. This resilience makes UV DTF an ideal choice for outdoor signage, product labels, and other items exposed to daily wear and tear.

Furthermore, businesses that prioritize durability in their printed materials can benefit significantly by reducing the need for replacements or reprints. This longevity not only enhances customer satisfaction but also contributes to a company’s bottom line, making UV DTF transfers an investment that pays off over time. The assurance that prints can withstand various conditions is essential for brand integrity and consumer trust.

Exploring the Versatility of Substrates in UV DTF Transfers

The versatility of substrates that UV DTF transfers can accommodate is one of its most appealing attributes. This technology allows printing on a diverse range of materials, including textiles, plastics, metals, and even wood, providing businesses the flexibility to expand their product lines. Whether creating custom apparel, personalized gifts, or promotional materials, UV DTF can adapt to meet various customer demands.

The ability to print on multiple substrates without requiring extensive equipment changes streamlines production processes and minimizes overhead costs. Companies can now cater to a broader audience without investing in specialized printers for each material type. This flexibility is especially beneficial for businesses looking to respond quickly to market trends or customer requests.

The Eco-Friendly Advantages of UV DTF Printing

As environmental consciousness rises among consumers, the eco-friendliness of printing methods has become a key factor in purchasing decisions. UV DTF transfers offer a more sustainable alternative compared to traditional printing methods, as they typically contain lower levels of volatile organic compounds (VOCs). This reduction means that UV DTF prints are less harmful to the environment and safer for indoor applications, aligning with the values of an eco-conscious marketplace.

Additionally, adopting UV DTF technology allows businesses to advertise their commitment to sustainability—a crucial differentiator in a competitive environment. Companies that incorporate eco-friendly practices not only attract environmentally-minded customers but also enhance their brand image, fostering a positive reputation that supports long-term growth.

Cost-Effective Production with UV DTF Technology

While the initial investment in UV DTF printing systems may be higher compared to traditional methods, the long-term cost benefits are substantial. The efficiency of UV DTF processes reduces ink usage and waste, which leads to lower production costs over time. Furthermore, the streamlined workflow associated with UV DTF technology eliminates several pre-treatment steps, thus cutting down on labor and production time.

This cost-effectiveness means that companies can increase their profit margins while still delivering high-quality products. Businesses that embrace UV DTF printing not only enhance their operational efficiency but also position themselves to take on more projects, ultimately driving revenue growth and sustainability.

Frequently Asked Questions

What are the key benefits of using UV DTF transfers in printing?

UV DTF transfers offer several key benefits, including high color vibrancy, durability of prints, versatility of substrates, eco-friendly printing options, and cost-effective production. These advantages make UV DTF a preferred choice for businesses looking to produce vibrant and long-lasting printed materials.

How does UV DTF printing ensure high color vibrancy in designs?

UV DTF printing utilizes UV-LED technology that allows for a broader color spectrum, resulting in high color vibrancy. This technology ensures that intricate designs and vibrant colors are accurately reproduced, enhancing the visual appeal of printed products.

What makes UV DTF transfers durable and long-lasting?

The durability of UV DTF transfers comes from the curing process that utilizes ultraviolet light. This process hardens the inks, making them resistant to scratches, fading, and environmental damage, resulting in long-lasting prints suitable for various applications.

Can UV DTF transfers be printed on different types of substrates?

Yes, UV DTF transfers are highly versatile and can print on a wide range of substrates including textiles, plastics, metal, and more. This flexibility allows businesses to cater to diverse customer needs and broaden their product offerings.

Are UV DTF transfers an eco-friendly printing option?

Yes, UV DTF transfers are considered eco-friendly because they use inks with lower levels of volatile organic compounds (VOCs) compared to traditional printing methods. This makes them safer for the environment and ideal for indoor use.

Is UV DTF printing cost-effective for businesses?

UV DTF printing can be very cost-effective in the long run as it reduces ink usage and waste, ultimately lowering operational costs. Additionally, the streamlined production process increases efficiency, allowing businesses to handle more orders and enhance revenue.

| Advantage | Description |

|---|---|

| High Color Vibrancy | UV DTF transfers provide a broader color gamut, allowing for intricate designs and vibrant colors that attract attention. |

| Durability and Longevity | The UV curing process makes prints resistant to scratches, fading, and wear, ensuring longevity. |

| Versatility of Substrates | Can be printed on various materials, including textiles, plastics, and metals, expanding business capabilities. |

| Eco-Friendliness | Uses fewer VOCs than traditional methods, making it safer for the environment and indoor use. |

| Cost-Effective Production | Reduces ink usage and waste, streamlining production and lowering long-term operational costs. |

Summary

UV DTF transfers represent a revolution in digital printing technology, characterized by numerous advantages that cater to modern business needs. High color vibrancy allows for stunning prints that stand out, while the durability ensures that designs maintain their appeal over time. The printing process is versatile, accommodating various substrates and supporting a wide range of products. Additionally, the eco-friendly nature of UV DTF printing aligns with today’s sustainability trends, making it an attractive option for environmentally conscious consumers. Finally, the cost-effectiveness of this technology streamlines production and enhances profitability, making it a smart investment for businesses. As the demand for innovative and high-quality printing solutions continues to grow, businesses would do well to explore the potential of UV DTF transfers, a key player in the future of printing.